Description

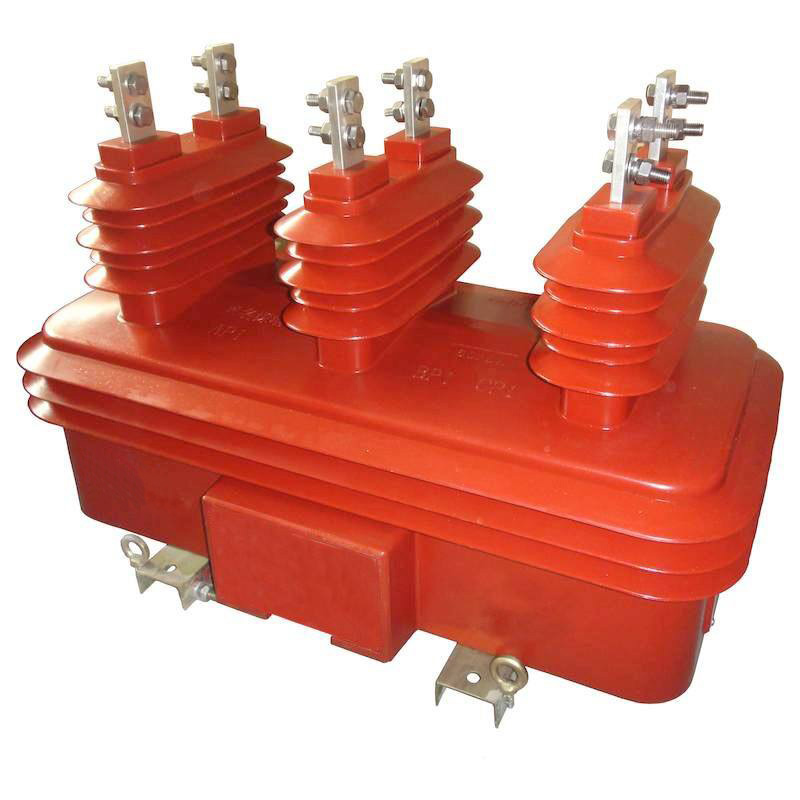

Suitable for injection and mould pressing. Special silicone rubber for producing ultra-high voltage, high-voltage composite insulators, composite arresters, line insulators and other high-voltage power transmission equipments.

| Physical Properties | Test Method | Unit | Data | |||||

| Model | NJ-152A-60 | NJ-152A-70 | NJ-152A-90 | NJ-152B-60 | NJ-152C-60 | NJ-152H-60 | ||

| Appearance | Under D65 Illuminant | / | Grey/Red/Customized, Inclusion-free. | |||||

| Shore Hardness | DIN 53505-A/ASTM D2240 | A0 | 65±5 | 70±5 | 88±5 | 65±5 | 65±5 | 57-63 |

| Elongation At Break | DIN 53504-SI/ASTM D412 | % | ≥240 | ≥180 | ≥150 | ≥220 | ≥220 | ≥220 |

| Tensile Strength | DIN 53504-SI/ASTM D412 | Mpa | ≥5.0 | ≥5.0 | ≥5.0 | ≥4.5 | ≥4.0 | ≥4.0 |

| Tear Strength | ASTM 624B | KN/m | ≥12 | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 |

| Hydrophobicity | DL-T376-2010 | / | HC1 | HC1 | HC1 | HC1 | HC2 | HC2 |

| Flammability | UL-94 | Class | V0 | V0 | V0 | V0 | V0 | V0 |

| Electrical Properties | Test Method | Unit | Data | |||||

| Dielectric Strength | IEC 60243 | KV/mm | ≥22 | ≥22 | ≥22 | ≥21 | ≥20 | ≥20 |

| Dielectric Constant | IEC 60250 | F/m | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 | ≤5.0 | 3.0-5.0 |

| Volume Resistivity | IEC 60093 | Ω·cm | ≥2×1014 | ≥2×1014 | ≥2×1014 | ≥2×1014 | ≥1×1014 | ≥1×1014 |

| Tracking & Erosion Resistance | IEC 60587 | Class | TM1A4.5≤2.5mm | TM1A4.5≤2.5mm | TM1A4.5≤2.5mm | TM1A4.5≤2.5mm | TM1A4.5≤2.5mm | TM1A4.5≤2.5mm |

| Dielectric Loss Angle Tangent | IEC 60250 | / | ≤6.0×10-2 | ≤5.0×10-2 | ≤6.0×10-2 | ≤4.0×10-2 | ≤5.0×10-2 | ≤4.0×10-2 |

| UV Aging Resisitance | UVA-340 | % | Pass | Pass | Pass | Pass | Pass | Pass |

| Sample Cured Condition | Curing temperature/time: 170℃×6Min. | ||||||

| Process Suggestion | Suitable for pressing/injeciton molding: suggested mold temperature 145C-165C for molding, time 5-15 mins, specific process according to size of housing to achieve best condition. | ||||||

| Package | 500KG/Carton; 25KG/ Carton | ||||||||||

| Storage Condition | Room temperature less than 25℃, do not contact water, avoid sun exposure. | ||||||||||

| Expiry Date | 10 months, suggest to finish within 3 months.If expired, can continue to be used after remilling and qualified inspection. | ||||||||||